Canada's dairy-products industry is made up of companies that process raw milk and cream. Primary products include pasteurized, packaged fluid milk and cream; cheese (natural, process, paste, spreads, curds); condensed, evaporated or powdered milk or cream; creamery butter, butter oil and whey butter; ice cream, ice-cream mix and ice-cream novelties; and frozen desserts (e.g., sherbets, ices). (See also Cheese and Cheese Making.) The industry operates under a supply management system, which controls the supply and stabilizes the price of Canadian dairy. The Canadian dairy manufacturing industry is highly regulated and it complies with regulations set by federal, provincial and industry partners (see Food Legislation).

Background

The first dairy product consumed by humans was fluid milk. While the cow is the major milk producer today, the milk of other mammals (e.g., bison, caribou, goat) is widely consumed in some parts of the world (see Dairy Farming; Goat Farming). Unquestionably, the first "processed" dairy product made from fluid milk was cheese (see Cheese and Cheese Making). It was standard fare in ancient Egypt, Greece and Rome and was frequently used as field rations by ancient armies. In Europe cheesemaking industries were run in monasteries, which produced varieties still made today. In Canada the popular Oka cheese was developed in a Quebec monastery (see Oka).

History of Canada’s Dairy Industry

Canada's modern, highly sophisticated, multibillion-dollar dairy-processing industry began in the early 1600s, when French settlers brought in dairy cattle. (See also History of Agriculture to the Second World War; Dairy Farming.) For the next 250 years, dairy production remained a farm or cottage industry. As towns and villages were established, fluid milk, butter and cheese were provided by local farmers, a situation that did not change until the 1850s. The modern factory method of cheesemaking was introduced by Jesse Williams, who built the first cheese factory in Rome, New York, in 1851. The first cheese factories in Canada were built in Oxford County, Ontario, in 1864 and at Dunham, Quebec, in 1865. About 20 years later, the factory method of cheese production was introduced to Scotland where it was called the Canadian cheese-making system.

By 1873 there were about 200 cheese factories in Canada. In 1873 a group of farmers established the first creamery in Canada at Athelstan, Quebec, but it survived for only about 10 weeks. Another creamery, started in Helena, Quebec, in the same year, remained in production for about 11 years before being converted to a cheese factory.

The first Canadian company to produce condensed milk was established in Truro, Nova Scotia, in 1883. Dried milk powder was manufactured for the first time by a company started in Brownsville, Ontario, in 1904. In 1900 modern large-scale milk distribution began in Toronto, Montreal and Ottawa; in 1927 homogenized milk was sold in Oshawa, a North American first.

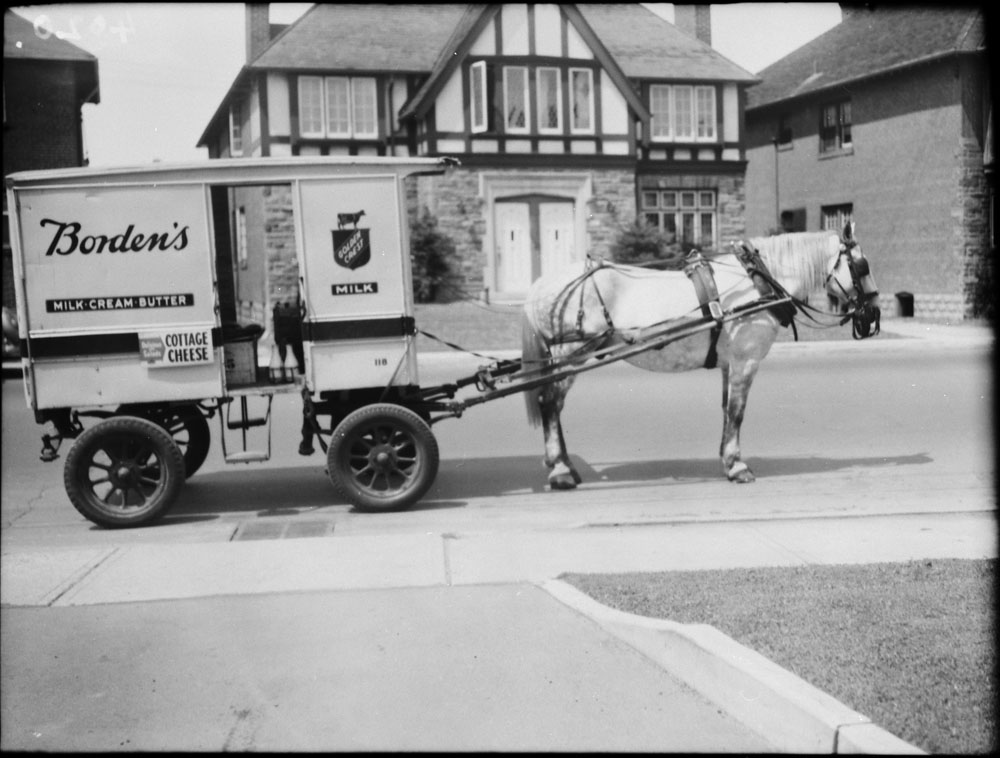

As is the case in a number of other Canadian food and beverage processing sectors, the dairy industry has experienced a substantial decrease in numbers of factories. Improvements in road and rail delivery systems, packaging methods and processing techniques permitted dairies to increase dramatically the distribution range of even their most perishable product, pasteurized fluid milk. Consequently, large, modern, centrally located production facilities have been constructed and many small, regional dairy companies phased out. In 1961 there were 1,710 dairies and by 1998, 270. Retail distribution of most dairy products has also changed significantly. In the 1940s and 1950s many dairy products were delivered door-to-door; today, consumers buy most dairy products directly from a grocery store and home delivery has disappeared.

Dairy Packaging

Major changes have also occurred in the packaging of pasteurized fluid-milk products. Until fairly recently, most fluid dairy products were in returnable glass containers; now most are in plastic, heat-sealed bags or in rigid containers made from paper laminated with plastic film (see Milk Bag). Both packaging types have significantly increased the shelf life of liquid dairy products. The latest development in milk packaging is the so-called "aseptic" (sterile) packaging. A totally sterile container is filled with fully sterile milk and sealed in a sterile environment before going to an outside carton-handling line. Fluid dairy products so processed are shelf stable at room temperatures for six months or more. The first Canadian aseptically packaged fluid milk was produced by a Montreal dairy in the mid-1960s. After a slow start, aseptic packaging facilities were established in most provinces.

Canadian Dairy Industry: 21st Century

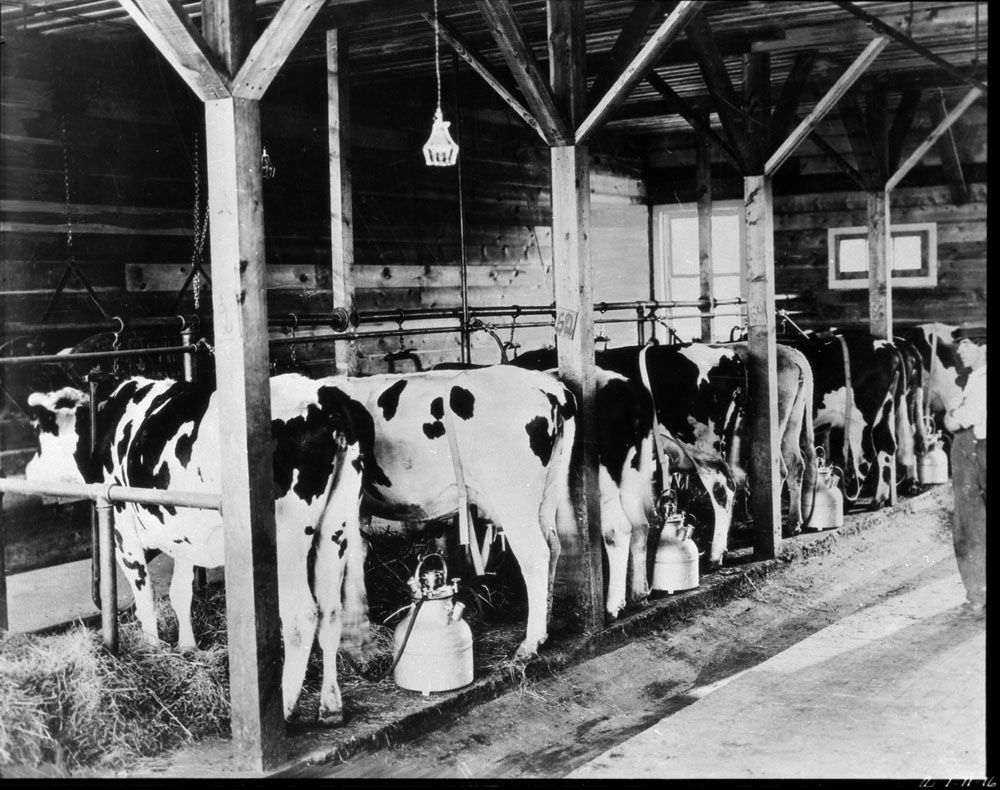

According to the Canadian Dairy Information Centre, total net farm cash receipts from dairying for 2024 stood at $8.88 billion, placing the sector second in agriculture behind red meats. In 2024, about 80 per cent of Canada's dairy farms were located in Ontario and Quebec, approximately 13 per cent were in the Western provinces, and approximately 5 per cent were in the Atlantic provinces. In 2024 there were approximately 1.375 million cows in Canada and 9,256 dairy farms producing 96.61 million hectolitres of milk. The primary breeds are Holstein (comprising more than 95 per cent of Canadian dairy herds), Ayrshire, Jersey, Brown Swiss, Canadienne, Guernsey, and Milking Shorthorn. (See also Dairy Farming.) In 2024, dairy products shipped from approximately 549 processing plants were valued at $19.3 billion. Approximately 28,830 people worked in the dairy manufacturing sector in 2024.

Share on Facebook

Share on Facebook Share on X

Share on X Share by Email

Share by Email Share on Google Classroom

Share on Google Classroom