Pipelines are systems of connected pipes used to transport liquids and gases — namely oil and natural gas — across long distances from source to market. More than 840,000 km of pipelines criss-cross the country. They represent part of the oil and gas sector which directly and indirectly employs approximately 740,000 people. According to Natural Resources Canada, the sector earns the government an average of $20 billion in royalties, fees and taxes each year (see Natural Resources in Canada). It also contributes nearly 11 per cent of Canada’s gross domestic product.

Pipelines, however, have been controversial in Canada. Pipelines help transport fossil fuels and research indicates that fossil fuel use, is significantly contributing to climate change. In recent years, Indigenous groups, environmentalists, municipalities and labour unions have opposed numerous pipeline projects due to the risk of contaminated local waterways from spills and leaks. (See also Environmental Movement in Canada).

Background

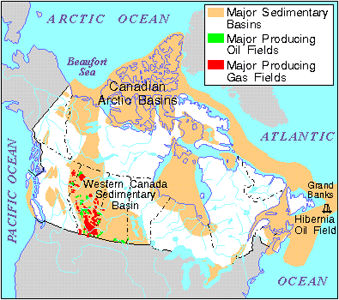

The discovery of fossil fuels in Canada began in Enniskillen Township, near Sarnia, Ontario, in the 1850s (see Petroleum Industries). The construction of pipelines to carry crude oil and natural gas to domestic (and eventually foreign) markets soon followed. For a century after the Sarnia-area oil discovery, the pace of pipeline construction was slow, with just three major routes (from Turner Valley, Alberta to Calgary; coastal Maine to Montreal; and the US Midwest to Ontario) in production.

But in the late 1940s, sufficient reserves of oil and natural gas were developed in Alberta at the Leduc No. 1 oil field to justify a monumental and rapid pipeline expansion to get crude oil to markets in Eastern Canada and the United States. By the end of the 1950s, new pipelines were being built to ship oil from distant wells into Edmonton and, from there, to Vancouver and south to link up with American pipelines. This capacity expanded greatly from the 1970s to 2010s with the construction of additional pipelines linking Canadian oil and natural gas fields with refineries in Alaska, Illinois and Oklahoma.

Major Pipelines in Canada

Today, more than 840,000 km of pipelines are laid out across Canada, beginning in Alberta and going west to British Columbia, north to the Northwest Territories, south to Texas, and east to Quebec. Gathering pipelines, feeder pipelines and transmission pipelines transport crude oil, natural gas and liquefied natural gas from wells to collection points, across provincial and national borders. Distribution pipelines deliver some natural gas products directly to consumers. According to the Canadian Association of Petroleum Producers, 99.999 percent of all the oil and gas moved by pipeline in Canada arrives at its destination.

Major crude oil pipelines currently operating in Canada include:

| Pipeline | Route | Capacity |

| Enbridge Mainline | Alberta to Wisconsin | 2.5 million barrels/day |

| TC Energy Keystone | Alberta to Illinois | 591,000 barrels/day |

| Trans Mountain Pipeline (Government of Canada) | Alberta to British Columbia | 300,000 barrels/day |

| Enbridge Line 9 | Sarnia, Ontario to Montreal, Quebec | 300,000 barrels/day |

| Spectra Express | Alberta to Wyoming | 280,000 barrels/day |

Major natural gas pipelines currently operating in Canada include:

| Pipeline | Route | Capacity |

| Nova Gas Transmission Ltd System | Alberta | 475 million cubic metres/day |

| TC Energy Mainline | Alberta to Quebec | 445 million cubic metres/day |

| Alliance Pipeline | British Columbia to Saskatchewan | 48 million cubic metres/day |

| Westcoast Pipeline | Northwest Territories to British Columbia | 45 million cubic metres/day |

| Maritimes and Northeast Pipeline | New Brunswick to Nova Scotia | 15 million cubic metres/day |

Many large-scale pipeline projects have been rejected by the federal government or withdrawn in recent years (see Politics and Controversy; Notable Pipelines Proposals). Enbridge’s Northern Gateway pipeline, from Alberta to Kitimat, BC, was rejected by Prime Minister Justin Trudeau in November 2016 over Indigenous opposition and concern about marine spills. TC Energy’s Keystone XL pipeline project was supported by the federal and Alberta governments. However, the project faced significant opposition and legal challenges on environmental grounds. On 9 June 2021, TC Energy and the Alberta government announced the termination of the Keystone XL project. Another TC Energy project, the Energy East pipeline, was intended to carry upward of 850,000 barrels of oil each day from Alberta to refineries in Quebec and New Brunswick. In October 2017, TC Energy abandoned Energy East and the proposed Eastern Mainline. The Mackenzie Gas Project, which would have transported natural gas from the Mackenzie Delta to northern Alberta, was cancelled by Imperial Oil and its partners in 2017.

How Do Pipelines Work?

A simple pipeline is a long length of connected pipes with pumps, valves and control devices to help convey liquids or gases. A pipeline network consists of gathering systems, trunk lines and distribution systems — parts that are analogous to the roots, trunk and branches of a tree. The gathering system transports a mixture of oil, gas and sometimes water from a production well to collection points, such as processing plants or refineries. Here, any water or contaminants in the pipeline are removed from the fossil fuel.

The trunk (consisting of the main pipelines) moves oil or gas at high pressures over long distances through large-diameter pipes from a collection point to markets. The energy needed to overcome friction in the pipes themselves is supplied by pump stations(for liquids) and compressor stations (for gas) spaced at intervals. As markets expand, the capacity of the trunk lines can be increased by installing parallel lines (known as “loops”) or adding more pumps or compressors. In the case of oil, trunk lines supply the refineries that, in turn, distribute the fossil fuel to retailers by truck or product pipelines.

Natural gas is withdrawn from the trunk line and delivered to consumers through the distribution system. This part of the network is the longest of the three systems. Typically, the pipes in this system are of small diameter and operate at low pressure.

How Are Pipelines Built?

Most pipelines are constructed of steel, although plastic and aluminum are occasionally used in the construction of natural-gas distribution networks. Steel pipelines are formed by welding sections of pipe together. After the welds are X-rayed to detect any flaws, the pipe is wrapped with a protective coating and buried. All pipelines, regardless of type, are then inspected and pressure tested before being put into service. For plastic lines of a small diameter, the pipe can be unreeled from a large spool pulled by a large tractor, a quicker method for laying pipeline.

The usual depth of burial is about 1.5 m for large pipes and slightly less for small pipelines, although some lines, like the Interprovincial crossing the Strait of Mackinac, are buried at depths exceeding 70 m. Canada is a world leader in winter pipeline construction, having developed unique trenching machines for permafrost and muskeg. Canadian pipeline companies have designed and constructed pipelines in Russia, China and Southeast Asia.

How Are Pipelines Monitored and Maintained?

Pipelines operate every day of the year. Computerized operation allows pressure, flow and energy consumption throughout the line to be continuously monitored. Computers can perform leak detection calculations quickly and initiate remedial actions in case of emergency, such as closing emergency valves, shutting off pumps and alerting repair crews (see also Computer Systems Applications). However, research suggests that operating stations catch only about 15–20 per cent of pipeline leaks. Companies also still frequently use “non-continuous” detection systems, which include dogs and visual inspections such as aerial monitoring from helicopters.

As a further precaution, periodic tests are made to assure a pipeline’s safe operation. Wax and foreign materials can be removed from oil lines by a process known as “pigging.” A “pig” is a bristle-covered cylinder that is pushed through a pipeline by fluid pressure, cleaning the pipe as it goes. The term pigging is derived from a squeal noise made as the bristles rub against the pipe wall. Today, “smart pigs” are equipped with sensors and recorders that monitor the inside of a pipeline for corrosion and weak spots. Pressure testing may be used in conjunction with, or in place of, “smart pig” inspections.

How Are Pipelines Regulated?

Background

Canada’s first Pipelines Act was passed in 1949. This federal legislation created guidelines and safety requirements for how and where pipelines were built. A decade later, the federal government established the National Energy Board (NEB), an independent agency that had the authority to regulate pipelines crossing provincial or international borders and the export of crude oil and natural gas. (See also Canada Energy Regulator (Formerly National Energy Board).)

In addition, the NEB considered issues related to pipeline construction, such as petroleum reserve estimates, costs, environmental factors, and engineering and safety practices. Historically, the NEB also conducted environmental assessments of proposed energy infrastructure projects. And in rare cases, a commission may be appointed to examine a particular project, as happened for the Mackenzie Valley pipeline in the1970s when environmental claims and Indigenous land claims complicated the review process beyond the board’s mandate.

Canadian Energy Regulator

On 28 August 2019, the Canadian Energy Regulator Act came into effect and the NEB was replaced by the Canada Energy Regulator (CER). Like the former NEB, the CER is an independent federal agency that regulates pipelines that cross inter-provincial and international boundaries. As part of its responsibilities, the CER reviews applications for new pipeline projects as well as the design, construction or abandonment of pipelines. The CER also regulates the export and import of natural gas and the export of oil.

Did you know?

Of the approximate 840,000 kilometers of pipelines across Canada, the CER regulates 73,000 kilometers. As of 2020, the CER regulated an estimated 100 pipeline companies in Canada.

Politics and Controversy

Pipeline construction has been a political flashpoint. A TransCanada (now TC Energy) pipeline, now known as the Canadian Mainline, was heavily debated in 1956,and intense controversy surrounded the Mackenzie Valley pipeline, a project that was indefinitely deferred in the 1970s, resurrected by Imperial Oil in 2004 and abandoned in 2017.

The Trans Mountain Expansion Project, originally owned by Kinder Morgan and now owned by the Canadian government, was also the focus of ongoing political conflict. In early 2018, a trade dispute broke out between British Columbia (a vocal opponent of the pipeline under NDP Premier John Horgan) and Alberta when Horgan’s government proposed a ban on increased shipments of bitumen from Alberta. Months of feuding between the provinces followed.

Did you know?

In May 2018, with Kinder Morgan threatening to abandon the project in light of ongoing opposition in BC, the federal government made the controversial decision to purchase the Trans Mountain pipeline and expansion for$4.5 billion. That August, the Federal Court of Appeal ruled on challenges launched by six First Nations, two environmental groups and the cities of Burnaby and Vancouver. The court found flaws in the government’s approval of the project, and the decision halted the expansion and ordered that parts of the process be redone (see Trans Mountain Expansion Project).

Indigenous consultation and approval of pipeline projects have become key factors in their acceptance by governments, regulators and the public. Before the successful legal challenge to the Trans Mountain Expansion Project, First Nations in British Columbia also used the court system and the government’s duty to consult to oppose the Northern Gateway pipeline. In the winter of 2018–19, two checkpoints set up by a group of Wet’suwet’en (see Dakelh) activists to block construction of TC Energy’s Coastal GasLink pipeline through their traditional territories made national headlines. Sympathetic groups held demonstrations across the country in support of the Wet’suwet’en pipeline opponents, 14 of whom were arrested by the RCMP in January 2019. Coastal GasLink is also divisive among the Wet’suwet’en, however, with some hereditary leaders and elected band councils supporting the project.

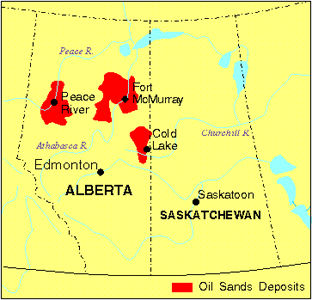

A central concern of many Indigenous communities is the risk that comes with situating oil and gas infrastructure in or near the habitats of wild food sources on which they rely. Health risks are also a concern at points of extraction: beyond contaminated drinking water is the fear that living in close proximity to fossil fuel extraction may increase cancer rates, as was shown in a University of Manitoba-Health Canada study of the Athabasca Chipewyan and Mikisew Cree First Nations in 2014 (see also Dene; Cree). Both of these communities are located close to Alberta’s oil sands.

Certain pipeline projects have received the support of Indigenous communities. For example, the Inuvialuit Regional Corporation, the Gwich’in Tribal Council and the Sahtu Pipeline Trust partnered on the Mackenzie Gas Project as the Aboriginal Pipeline Group (see also Inuvialuit; Gwich’in; Sahtu Got’ine). The Eagle Spirit pipeline, a proposed alternative to Northern Gateway, was backed by several First Nations seeking to build an Indigenous-owned pipeline.

Environmentalists have begun to insist that oil companies, governments and the CER (formerly the NEB) consider the upstream greenhouse gas implications of pipelines that facilitate the extraction and combustion of more fossil fuels. At the Paris Climate Change Conference in December 2015, Canada agreed to reduce its carbon emissions to 523 megatonnes per year by 2030, equivalent to a 30 per cent reduction below 2005 levels. While Canada is already unlikely to meet its Paris targets, some have argued that task will be made impossible by increasing pipeline capacity linked to the Alberta oil sands. (See also Climate Change .)

The system for pipeline approval itself has also been criticized. In the winter of 2016–17, a government-appointed expert panel met with industry, stakeholder and Indigenous groups as part of a massive push to overhaul how the NEB (as of 2019 the CER) reviews and approves projects in the future. In August 2020, the CER announced the establishment of an Indigenous Advisory Committee (IAC), which advises the CER’s board of directors “on how the CER can build a renewed relationship with Indigenous peoples.” (See also Reconciliation in Canada.)

Share on Facebook

Share on Facebook Share on X

Share on X Share by Email

Share by Email Share on Google Classroom

Share on Google Classroom