Like most industrial activities, mining involves risk. However, contemporary mining in Canada is much safer than it once was. The old image of miners with picks and shovels no longer holds true. Many contemporary miners use robotics, computers and high-tech equipment, making mining as safe or safer than comparable heavy industrial activities such as construction, logging or even farming. (See also Coal Mining Disasters; Safety Standards.)

Hazards

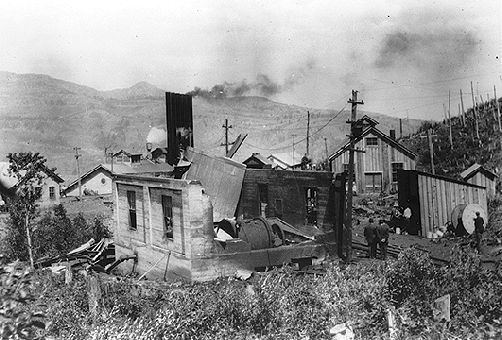

Hazards are inherent to working with heavy equipment, explosives and large vehicles. This is particularly so in open-pit mining, in which high-voltage electrical power is supplied to mobile equipment, such as draglines and shovels. There is also a risk of rocks flying through the air during large-scale blasting operations. Underground mining involves working in confined space with restricted illumination. Noise, engine exhaust emissions, mineral dusts and gases are also hazards, especially underground. The latter pose additional hazards in coal mining when methane is released from the rock strata. Within a certain range of concentration in the atmosphere (between 5 and 15 per cent), methane is highly explosive. Accidents are often devastating, causing much damage and loss of life.

Miners might also fall or be struck by pieces of falling rock. Falls by miners can be reduced by increased attention on the work and surroundings, by safer working practices and by training. Rock falls are being reduced in frequency by better blasting practices, by the immediate removal (or scaling) of potentially hazardous slabs or blocks of loosened rock, and by rock reinforcement. The common practice is to never walk beneath rock that has not been inspected, scaled and bolted. The science of rock mechanics and its practical counterpart, ground control, are used to ensure that the design of mine openings takes into account the geological features, the strengths of the rocks, and the local stresses in the rock mass. Historically, this level of mine engineering did not take place.

Enhanced Working Environment

In mining, continuous improvements are being made in equipment, working practices and protective gear, with a view toward enhancing the working environment. Sensors are used to detect the performance characteristics of equipment, various gases in the mine atmosphere and movements in the rock.

Government Regulation

In Canada, mining health and safety is mostly the responsibility of the provincial and territorial governments. Each province and territory has its own legislation and a Chief Inspector of Mines. The federal government is responsible for certain federally owned mines in the provinces and, through the Canadian Nuclear Safety Commission, for uranium mines.

Share on Facebook

Share on Facebook Share on X

Share on X Share by Email

Share by Email Share on Google Classroom

Share on Google Classroom